Servo-controlled Ultrasonic Metel Welder SDB |

|

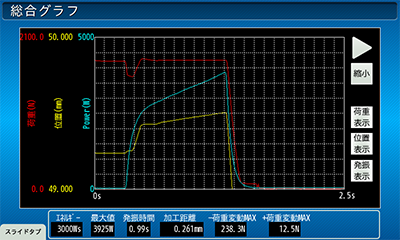

This Servo-driven press system with our unique and impressive press control can promptly react to maintain a constant press force despite the material being deformed during the ultrasonic welding process! Thus, ultrasonic energy can be efficiently and effectively transmitted to a work piece, resulting in a shorter cycle time than a conventional ultrasonic welder utilizing a pneumatic press. An Effective and User-friendly tool for quality assurance and quality control Since ultrasonic energy and press force are completely digitally controlled, ultrasonic energy, time, peak power, weld height and weld force are constantly measured throughout the welding process. These measurement results can be utilized for quality assurance and quality control. Highly rigid structure for precise press force control The SDB has a highly rigid servo press structure along with a mechanism that can minimize the influence of ultrasonic vibration to the load-cell which ensures precise press force control and consistent welding quality. |

MODEL SDB |

|

|

|

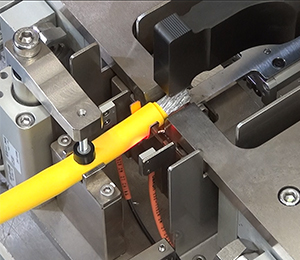

Provides reliable bonding in key manufacturing areas such as automotive wire harnesses, lithium ion batteries, and power electronics.

|

|

|

![]() Advantages of ultrasonic metal welding using servo-press control

Advantages of ultrasonic metal welding using servo-press control

|

Ultrasonic metal bonding with innovative servo-press control offers significant advantages in repeatability and reliability over a conventional pneumatically driven press system. In addition, press force and displacement of weld material can be monitored throughout the weld process, and the weld data with key parameters can be stored and utilized to increase your efficiency and can be used for quality assurance.

Using the SDB will also extend the life of tools such as horns and anvils which is a great advantage. Pneumatic driven press system on the other hand accelerates wear and tear on these tools because it is not able to react as quick as a servo-driven press system during the weld process. A Pneumatic driven press system has the problem of applying excessive ultrasonic power and pressure to the weld material in order to compensate for lower energy transmission due to its slower reaction speed. With our SDB welder you no longer have to worry about this issue. Since servo-press system enables welding with lower ultrasonic energy and pressure, it prevents wear and tear due to overload of the ultrasonic generator and the servo-press itself. Therefore, the servo-press system will enable you to reduce maintenance cost and furthermore cutdown on downtime in production. |

|

![]() For more detail, please CONTACT US

For more detail, please CONTACT US