Solder Ball Mounter STM-II Advance |

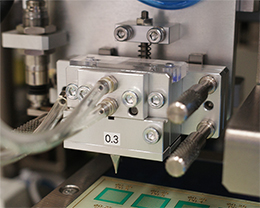

Ball separation unit is simply interchangeable |

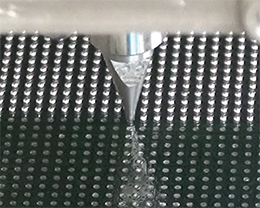

Single-shot ball placement on a BGA |

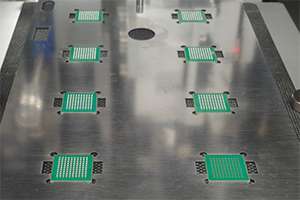

Ball placement on multiple BGAs |

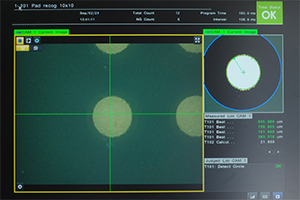

Vision system for automatic offset of ball placement position and missing ball inspection |

Video 0.3mm solder ball placement.

![]() Specification

Specification

| Ball diameter | 0.2mm – 1.0mm dia. |

| Placement accuracy | within 50 micron (2mil) |

| Ball placement speed | 0.7sec – 0.9sec/sphere |

| Board size | 60mm x 120mm standard, custom fixture for multiple BGAs(option) |

| Camera unit | Camera for manual alignment and visual inspeciton, vision system available as an option |

| Utility | 100V 5A, or come with external transformer for 110V-230V. |

| Dimensions | D720 x W880 x H870mm(with LCD monitor) |

■Related Products

| Micro solder ball placement system STM-Micro |

|

|||

| STM-Micro meat demand of micro ball mounting, capable of handling micro solder ball of 80micron diameter or above. |

![]() For more detail, please CONTACT US

For more detail, please CONTACT US