BGA Re-balling Unit SMU-50 |

|

Precision Reballing unit SMU-50 is suitable for prototyping and reballing of ball grid allay components such as BGA and CSP. The system has unique micro alignment function which enable user to simply and accurately align the position of metal stencil in X-Y-theta and also control the gap between the surface of component and stencil for flux printing and ball placement. This is to minimize the failure of ball placement such as misalignment or lack of solder spheres on the ball pads. The stencils are available in many standard patterns and simply replaceable from stencil holder. |

|

![]() The standard system includes the following items.

The standard system includes the following items.

|

1) Reballing main unit. 2) Metal stencil holder for flux printing 3) Metal stencil holder for ball positioning 4) 1 set of metal stencils and component nest 5) Spatula for flux squeezing 6) Ball leveler 7) Ball insert ring |

|

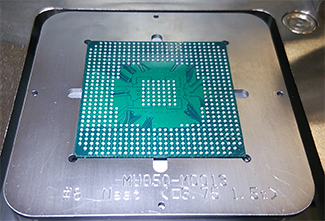

Reballing BGA with 0.3mm dia. solder spheres |

BGA nest with vacuum fixing |

![]() Capability/Function

Capability/Function

| Ball diameter | Larger than 0.2mm diameter |

| Component size | 5 – 50 mm sq. Max. t = 3.0mm |

| Alignment range | X axis: 3mm, Y axis: 3mm, Z axis: 5mm, theta: 5 degree, |

| Utility | Single phase, 220V, 10W for vacuum pump (pressure requirement: Max. 24kpa) |

| Dimensions | 185(W) x 265(D) x 220(H)mm |

| Utility | Approx. 6kg |

| Weight | 750(W) x 540(D) x 385(H)mm |

![]() Option Items

Option Items

![]() Related Product: Solder Ball Placement System / Ball Mounter STM-203FB

Related Product: Solder Ball Placement System / Ball Mounter STM-203FB

![]() For more detail, please CONTACT US

For more detail, please CONTACT US