Table-top vacuum reflow oven TVF200 |

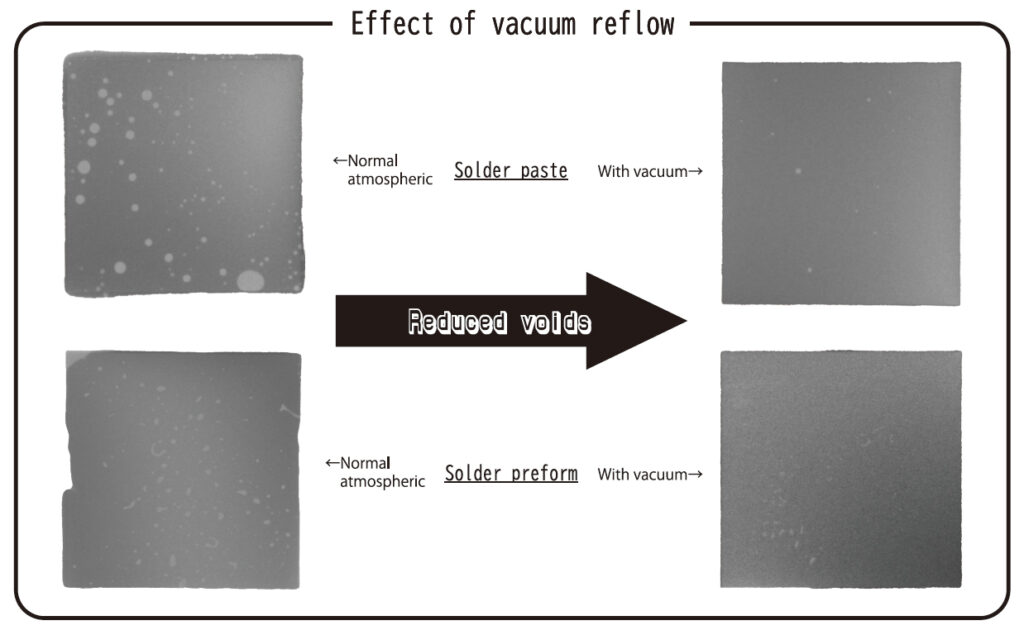

TVF200 vacuum soldering process significantly reduces voids inside the solder by changing the pressure inside the process chamber, enabling high-quality void-free soldering.

|

|

| Void reduction effect by vacuum reflow soldering. X-ray image of a sample of 10x10mm copper pieces reflow soldered. The photo on the left shows reflow soldering at constant pressure (atmospheric pressure), and the photo on the right shows reflow soldering while varying the pressure inside the process chamber. |

|

| In atmospheric reflow, there is no pressure change in the atmosphere, so the solder solidifies while voids remain trapped. | |

| By varying the pressure inside the process chamber from atmospheric pressure to a vacuum of around 10 Pa, voids in the solder can be significantly reduced. |

|

Options such as dry vacuum pumps, formic acid bubblers, and dedicated racks are also available. |

![]() Specifications

Specifications

| Effective heating area | 200mm x 200mm |

| Set temperature | Max 450℃ |

| Ultimate vacuum | 10Pa (depends on dry vacuum pump capacity) |

| Supported gas | Nitrogen gas, formic acid mixed gas, forming gas, He gas, etc. |

| Dimensions | W622mm x D597mm H775mm (including indicator light) |

| Weight | Approx. 65kg |

| Power supply | Three-phase 200V, 8kW |

■Related product

![]() Vacuum & Pressure Reflow Oven VPF300

Vacuum & Pressure Reflow Oven VPF300

![]() For more detail, please CONTACT US

For more detail, please CONTACT US